Migrate Access database application to QAD 2020AE

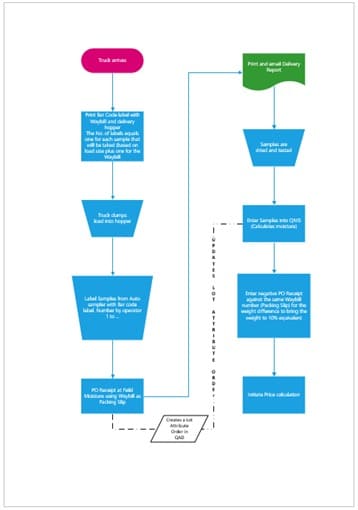

Objective – Access database was used for all Nut-in-Shell (NIS) intake recording and reporting along with grower payments calculations. The whole functionality record receipt and payments for Nut in Shell (NIS) items.

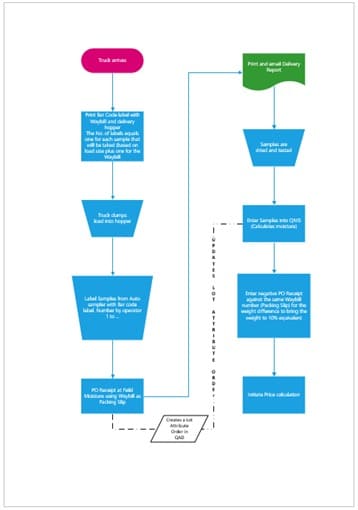

The whole process is migrated to QAD 2020AE and screens and reports developed as per their existing application in Access Database. Ultimately the NIS system allows for the entry of a receipt of Nut in Shell (NIS) from a supplier (Grower) that has a contracted Payment Scheme and subsequently Laboratory test results are entered against this delivery. The test results along with the Payment Scheme determines the price

to pay the grower for the delivery that updates the Supplier Invoice in Accounts Payable.

At the time of receipt, the Batch number is known e.g., 21-0001 being the YY- current year and a sequential number, 0001 is the first delivery of the season. This Batch number will be used as the Lot/Serial number for the delivery and the Waybill number will be entered as the Packing Slip and the (Lot) Reference. This gives the visibility of the stock in the Silo as it is being filled. At a later date after the Silo is closed off, the Reference will need to be changed to be the Batch number to simplify the issue of NIS to the Cracking process and facilitate the movement by license plate. This will be done by way of a Repetitive manufacturing entry at the time the Silo is closed off or dried.

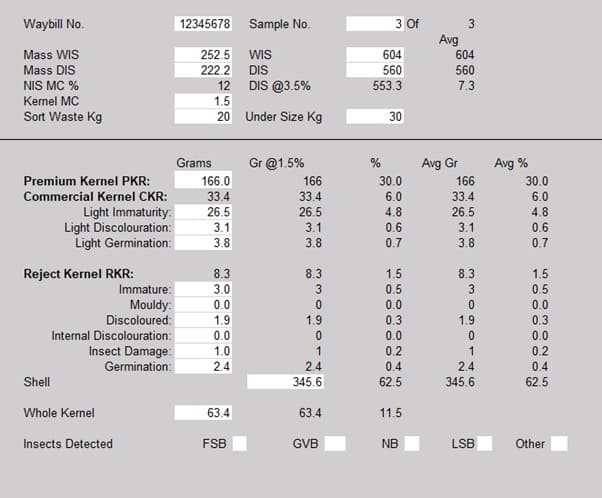

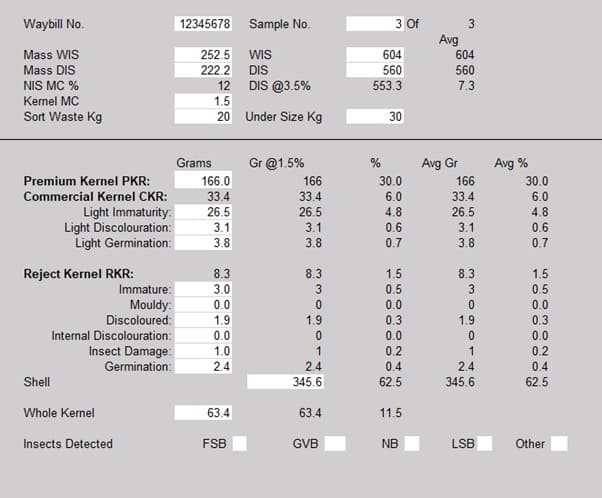

The weight at the time of receipt is the “Field” weight at an unknown moisture. Each of the

deliveries into the silo will continue to go into the silo with the same Batch number and unique Waybill numbers as the Reference (Lot/Reference). Quality tests will be entered at a later time including the moisture % as Quality test results. The known moisture will be used in calculations for weight. An example of this will be that the grower supplied 630 kg at 18.1% moisture and the weight at 3.5% moisture is calculated to be 540 kg (approx.). The equivalent 10% weight will be calculated as 573 kg to be presented on reports.

When the Silo is “Closed Off” and all the deliveries have been tested for Moisture content, a

production event will be run in QAD to consume all of the References (Waybills) reusing the Batch number and reducing the weight from Farm weight to the 10% or 3.5% weight (yet to be agreed, probably 10% as this is the standard.) It is therefore important to note that the Supplier Payment calculations are based on the initial receipt weight adjusted to 10% moisture based on the actual moisture content recorded in the Lot Attribute for the delivery.

The Moisture will be entered into the “Assay” field rather than the Test result if this data is too difficult to get from the database tables and is more visible in QAD standard Browses. This will be used in the calculation for payment to suppliers. An inventory Browse with a Button to the Inventory Detail Maintenance screen to enter the Assay Field will be built. Note, the Assay field is also available through Lot Attributes. Also, this Browse will have a built-in calculation to convert to 10% weight and 3.5% weight shown in different columns based on the Assay field which holds the “Farm” moisture%.

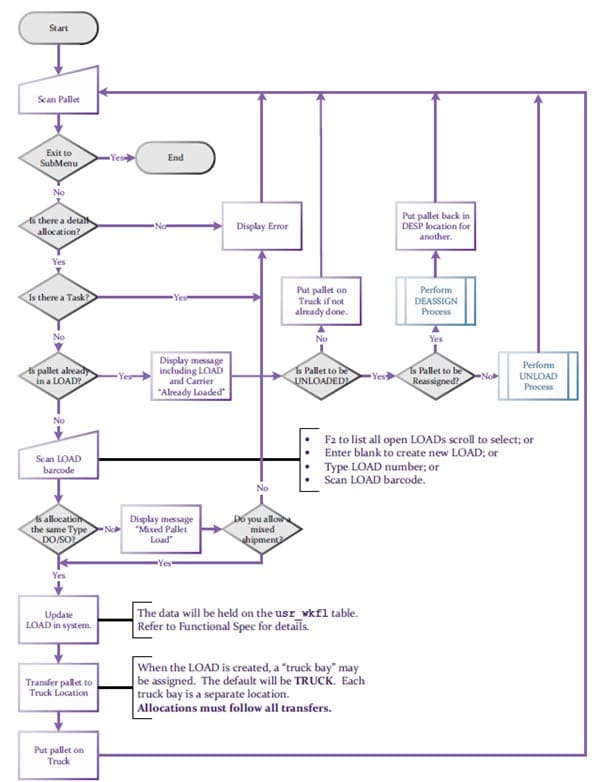

Transfers from Silo to Silo – Silos will be Locations. Transfers will be done in QAD or via RF Express, at completion of physical transfer.

Drying Ovens in the Laboratory will be Locations and the sample stock will be transferred to each oven. Typically, this is 500 grams per sample. This will give visibility of the Supplier, Batch, and Reference (Waybill). When this stock comes out of the oven this stock will be transferred from the Oven to the Lab location for retention samples. These can be viewed over time and after 2 months, this can be written off when it is physically disposed of. These samples are used to determine the key elements of the delivery, i.e. moisture, Premium Grade, Commercial Grade, and Rejects.